Troubleshooting: White Ink Flow Problems

Problem

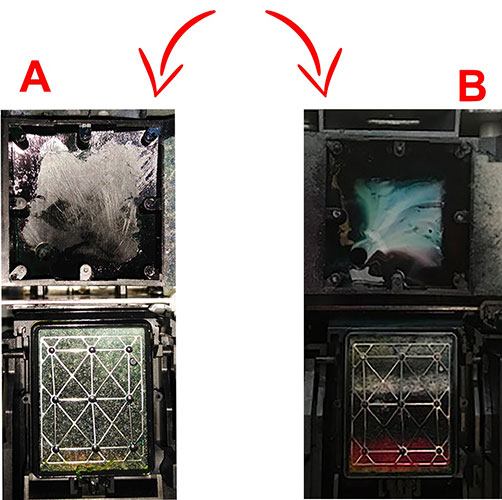

Does your capping station and sneeze tank look like A or B?

Solution

White ink flow problems can bring production to a halt. In most cases it can be resolved before becoming a costly repair with preventative measures. If your experiencing white ink flow issues, we need to determine if the problem is hardware or software related.

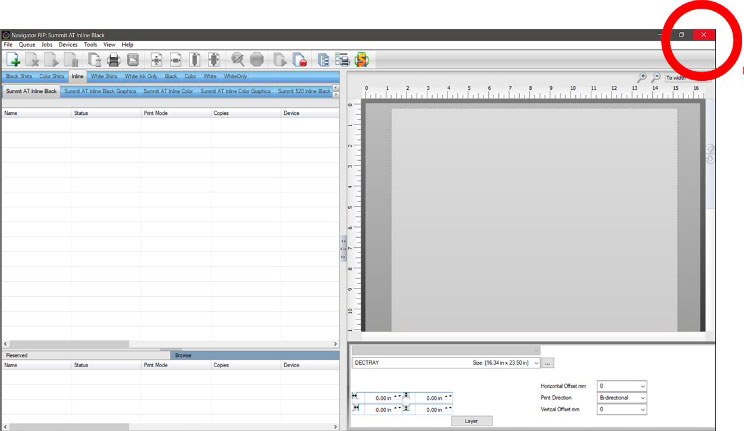

Note: This document is for only Summit Models printing through "Navigator Rip Software".

If your capping station and sneeze tank look like A your problem is most likely hardware related.

- Using your ink syringe; pull from the waste ink lines until the ink in the syringe is a light greyish/green color. This step may need to be repeated several times.

- Perform a head clean to remove excess ink from the bottom of the print head.

- If steps one and two do not resolve the problem please contact a MESA technician.

If your capping station and sneeze tank look like B your problem is most likely software related. Please see the instructions below.

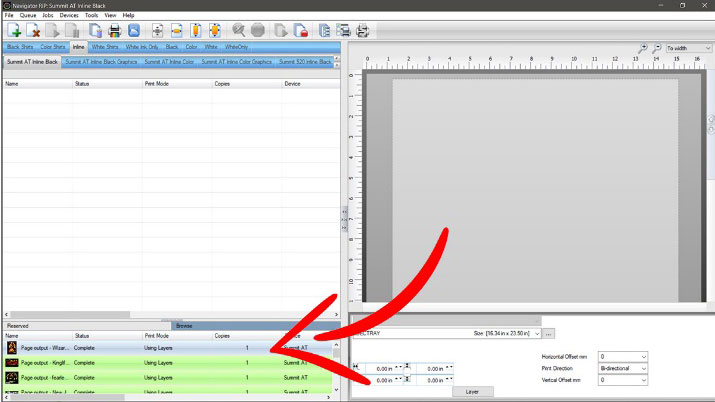

- Select the file at the top of the Completed Jobs list. Then hold the "CTRL" button while pressing "A" on the keyboard.

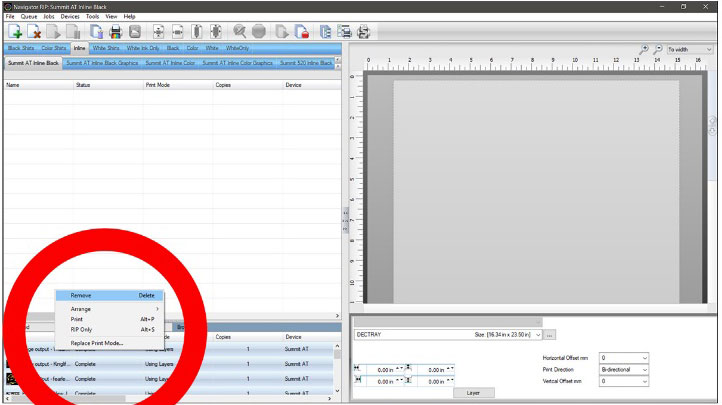

- Right click on the top job and select Remove.

- Repeat steps 1 and 2 for all other print jobs.

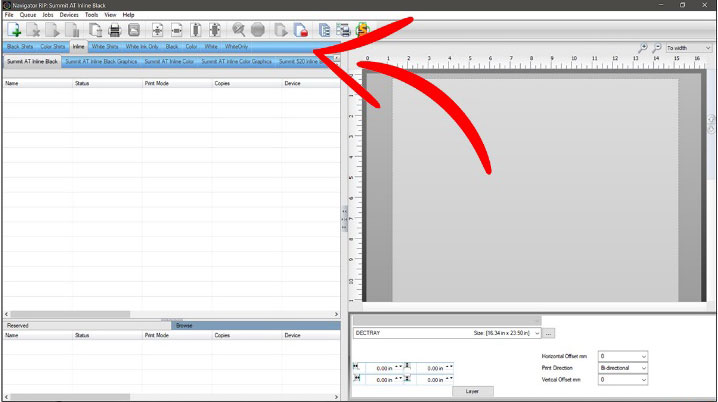

- Close Navigator.

Now please restart your printer and software. If this did not resolve the problem please contact a MESA technician.